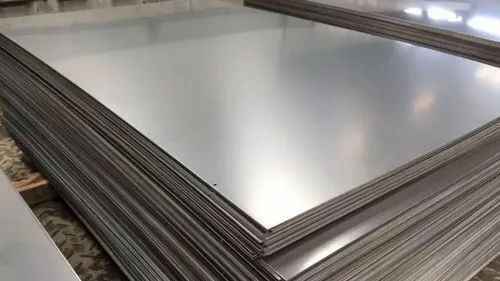

Stainless Steel Sheet

Product Details:

Stainless Steel Sheet Price and Quantity

- 1 Kilograms

Stainless Steel Sheet Trade Information

- 100 Kilograms Per Day

- 1 Week

Product Description

The salient features of Stainless Steel Sheet:

- Accurate dimension

- Sturdy construction

- Excellent finish

- High tensile strength

- Corrosion resistant

FAQs of Stainless Steel Sheet:

Q1: What is a Stainless Steel Sheet?

A1: A Stainless Steel Sheet is a level, flimsy piece of stainless steel that is accessible in different sizes, thicknesses, and grades. It is broadly utilized in development, producing, and different enterprises because of its consumption obstruction, sturdiness, and flexibility.

Q2: What are the normal grades of stainless steel utilized for sheets?

A2: Stainless Steel Sheets are accessible in various grades, however probably the most generally utilized ones incorporate 304, 316, 430, and 201. The decision of grade relies upon the particular application and required properties.

Q3: What are the size and thickness choices for Stainless Steel Sheets?

A3: Stainless Steel Sheets are accessible in many sizes and thicknesses, from slim sheets to thicker plates, to meet different modern and assembling needs. The particular aspects can shift by producer and provider.

Q4: Can Stainless Steel Sheets be utilized for open air applications?

A4: Indeed, stainless steel sheets are appropriate for open air use because of their erosion opposition. In any case, the life span of the material can be impacted by ecological elements, so legitimate consideration and upkeep are fundamental for delayed open air use.

Q5: Can Stainless Steel Sheets be cut or molded?

A5: Indeed, Stainless Steel Sheets can be cut, molded, and shaped utilizing different strategies, for example, laser cutting, plasma cutting, waterjet cutting, shearing, and twisting. The decision of technique relies upon the thickness and intricacy of the ideal shape.

Q6: Are Stainless Steel Sheets impervious to consumption?

A6: Indeed, stainless steel sheets are known for their astounding consumption obstruction. The chromium content in stainless steel shapes a defensive oxide layer on a superficial level, forestalling rust and erosion.

Q7: Can Stainless Steel Sheets be welded?

A7: Indeed, most stainless steel sheets are weldable utilizing normal welding strategies like TIG (Tungsten Latent Gas) welding, MIG (Metal Dormant Gas) welding, and stick welding. Notwithstanding, the decision of welding strategy and filler material might change relying upon the grade and application.

Q8: What are the upkeep prerequisites for Stainless Steel Sheets?

A8: Stainless Steel Sheets are for the most part low-support. Ordinary cleaning with gentle cleanser and water, trailed by drying with a spotless material, can assist with keeping up with their appearance. For particular applications, legitimate support might incorporate passivation or explicit cleaning methods.